|

|

|

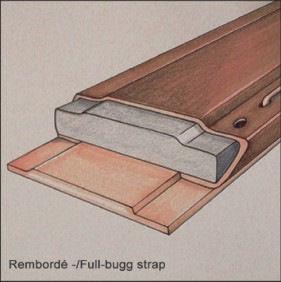

Rembordé -/Full-bugg strap

( approx. 140 production steps )

In the production of a rembordé or full-bugg strap, the upper leather is wrapped around a breathable, natural cotton fleece and glued. Next, the folded upper leather is glued deep into the seem of the lining leather, so that no bacteria can penetrate from the sides. Finally, all components are stitched together. The advantages: The strap is very stable, soft and very durable like a welted shoe.

|

|

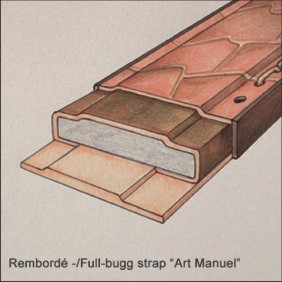

Rembordé -/Full-bugg strap

"Art Manuel"

( approx. 172 production steps )

This labour intensive technique is reserved for the most exclusive straps. An additional layer is placed on top of the strap. Virtually any leather can be used on this layer, such as hornback crocodile, which would be too stiff for conventional techniques. Then the strap is compressed, the edges are smoothed by using heat, sanded down and then painted five times with edge dye. Loops and buckle flaps are stitched by hand.

|

|

|